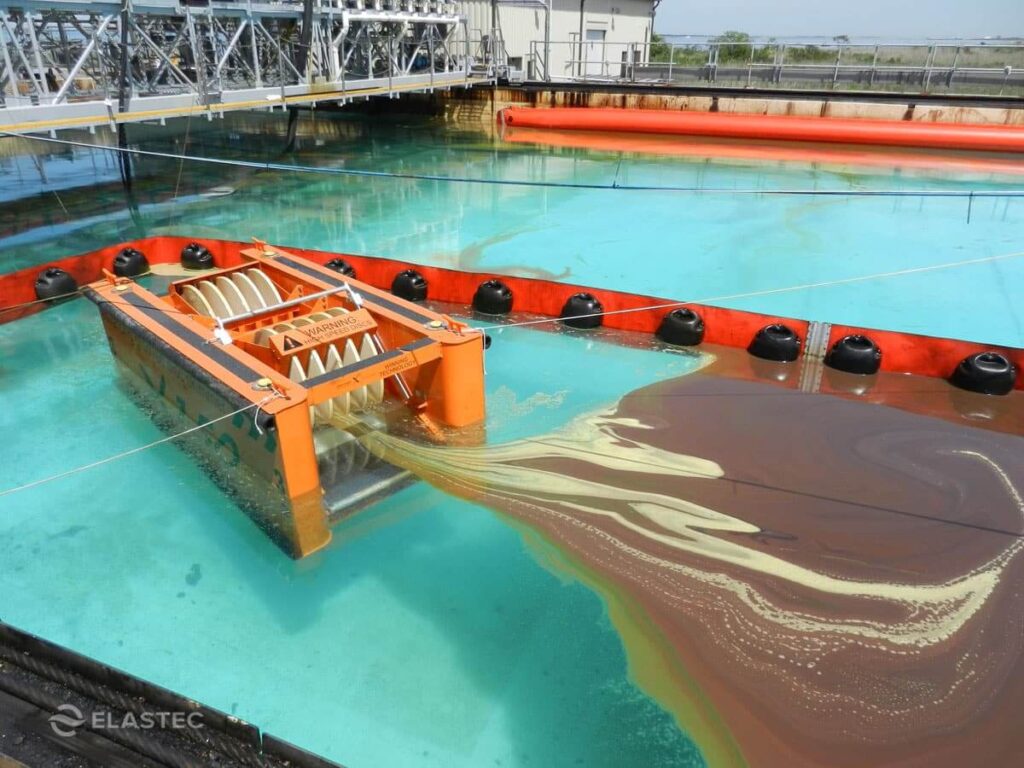

Since the early 1990s, when the U.S. Coast Guard regulations codifying the Oil Pollution Act 90 came into force, some spill response equipment manufacturers assigned unrealistic Nameplate Capacity ratings to their oil skimmers, loosely based on the ability of an integral pump to move water through the system. (Nameplate Capacity is the number used to represent skimmer performance.)

But knowing how much water a pump can move provides very few clues to how much oil a skimming device might actually be able to recover. Testing to a published American Society for Testing and Materials (ASTM) standard, by an independent third party test facility such as Ohmsett in Leonardo, New Jersey, can yield two important performance parameters: Oil Recovery Rate (the amount of oil in the recovery stream) and Oil Recovery Efficiency (oil in the recovery stream as a percentage of total fluid).

Elastec/American Marine has invested hundreds of thousands of dollars over the last decade conducting these tests on our skimmers. We are one of a very small number of spill equipment manufacturers who offer certified, third-party test results. Oil skimmer performance testing like this provides our customers with closer-to-real numbers they can use in response planning. These standards provide a level playing field for comparing one skimmer to another. In Elastec’s quest for optimum oil skimmer recovery rates, we also learn how subtle changes in power settings and floating condition affect performance – something we can share with our customers in our operating manuals and during hands-on training.

But, perhaps most importantly, in a company that strives for improved product performance every day, it gives us a consistent and repeatable basis for measuring our progress.

Contact us today to learn more about Elastec/American Marine’s oil skimmer Nameplate Capacities.

Connect With Us

Sign up for our newsletters to receive the latest news and product information from Elastec.