REELPAK AUTO-INFLATION CONTAINMENT BOOM

ReelPak is a auto-inflating containment boom that can be easily and quickly deployed and retrieved. With an integrated coil structure and compartmented float sections, the boom will stay inflated and buoyant even if a fabric tear or light damage occurs.

Available in both 250 ft / 76 m and 125 ft / 38 m sections and multiple sizes, ReelPak is suitable for most scenarios.

ReelPak Booms are constructed of heavy duty, 100% polyurethane coated, high visibility yellow fabric with RF welded seams for maximum strength. The boom is also constructed of high quality stainless steel coils that automatically expand the boom to its full, continuous cylindrical shape as it is reeled from the storage spool. These coils also assure continuous freeboard without pressure.

Closed cell foam flotation provides reserve buoyancy of more than 150% of the boom weight, assuring working freeboard and survival of the boom even if damaged extensively.

Float compartmentation prevents boom flooding from local damage; and even then, the boom is automatically auto-bailing during recovery to drain any incidental water. ReelPak Boom does not depend on hermetic sealing of air chambers to maintain freeboard since the reserve buoyancy foam flotation and stainless steel coils work together to ensure working freeboard at atmospheric pressure, even if the boom is damaged.

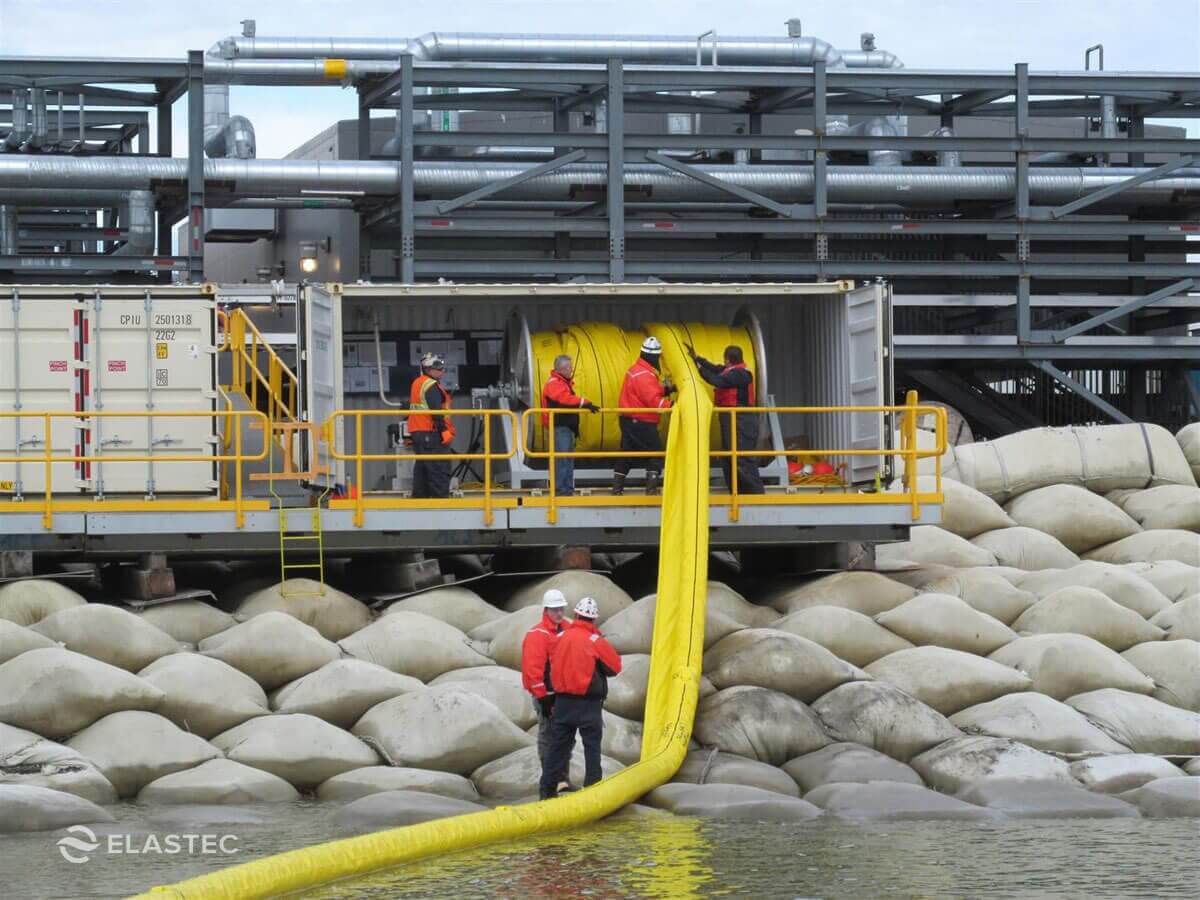

REELPAK PHOTO GALLERY

REELPAK VIDEO GALLERY

ReelPak Containment Boom Specifications

| Model | Inland/Choppy | Open Harbor | Light Ocean | Offshore | Hi-Seas 600 | Hi-Seas 800 |

| Float Diameter | 8 inch / 20 cm | 11 inch / 20 cm | 14 inch / 36 cm | 18 inch / 46 cm | 24 inch / 61 cm | 32 inch / 81 cm |

| Freeboard | 7 inch / 18 cm | 10 inch / 25 cm | 13 inch / 33 cm | 16 inch / 41 cm | 22 inch / 56 cm | 30 inch / 76 cm |

| Draft | 13 inch / 33 cm | 16 inch / 41 cm | 20 inch / 51 cm | 26 inch / 66 cm | 35 inch / 88 cm | 44 inch / 112 cm |

| Buoyancy | 22 lb / 33 kg | 41 lb / 63 kg | 67 lb / 98 kg | 110 lb / 164 kg | 195 lb / 291 kg | 345 lb / 514 kg |

| Weight | 1.7 lb/ft / 2.5 kg/m | 2.7 lb/ft / 4.0 kg/m | 3.4 lb/ft / 5.1 kg/m | 6 lb/ft / 9 kg/m | 8.5 lb/ft / 12.7 kg/m | 11.5 lb/ft / 17.2 kg/m |

| Storage Volume | .11 ft3 / .003 m3 | .21 ft3 / .006 m3 | .28 ft3 / .008 m3 | .41 ft3 / .012 m3 | .67 ft3 / .019 m3 | 1.0 ft3 / .028 m3 |

| Tensile Strength (in thousands) | 25 lb / 11 kg | 35 lb / 16 kg | 45 lb / 21 kg | 60 lb / 27 kg | 70 lb / 32 kg | 100+ lb / 46 kg |

| Temp. Range | -65° to +170°F / -54° to +77°C | -65° to +170°F / -54° to +77°C | -65° to +170°F / -54° to +77°C | -65° to +170°F / -54° to +77°C | -65° to +170°F / -54° to +77°C | -65° to +170°F / -54° to +77°C |

Deployment & Recovery

ReelPak Boom Systems are rapidly deployed and recovered at atmospheric pressure. Both boom deployment and recovery are continuous operations. There is no need to halt either process to inflate or deflate air chambers, open or close valves. ReelPak booms do not require any auxiliary inflation equipment to achieve and maintain full operational performance.

Performance

Since the flotation chamber is a continuous, flexible, cylindrical configuration, ReelPak Booms maintain constant freeboard and provide best articulation and conformance in wind and waves. The section connectors are also flexible and have the same shape and strength as the boom. The continuous, uniform, cylindrical flotation throughout the float and end connections provide the best possible shape for containing and diverting oil without creating agitation and emulsification of oil. ReelPak Booms have exceptional wave conformance in turbulent and confused seas.

The boom is easily towable for extended periods of time at over 10 knots in 300 meter strings and longer. The boom resists current forces of 4 or 5 knots relative velocity while anchored or in catenary towing without detectable reduction of flotation chamber volume and performance.

Continuous Handles

ReelPak is provided with continuous handles on both sides of the boom on models with 18 inch floats and above. These handles provide a great convenience for handling on shore and in the water as well as during recovery to the reel. Located mid-point alongside like rubbing strakes or continuous side fenders, they are ideal for attaching anchor buoys, lights or positioning signals. The handles also provide some additional stand-off abrasion resistance against contact with vessels, docks, pilings, platforms, etc. Continuous handles are available as an option on models smaller than 18 inches.

Markings

Anchor points are physically located on the ballast chain. The location of each anchor point is clearly marked on the float section of the boom.

Skirt Information

ReelPak Boom skirts are constructed of the same heavy-duty, 100% polyurethane-coated fabric as the float section. Inside a fabric pocket at the bottom or ballast part of the skirt is a 3/8” high-test galvanized proof coil chain. This chain serves as the main tension member of the boom. Anchor connection locations are heavily reinforced and stabilized in position.

High-Load Webbing Strap (optional)

10,000 lbs of additional tensile strength can be added by including a High Load Webbing Strap running the full length of the boom and joined at each section with shackles. Standard on models 24 inches and above. Optional on models smaller than 24 inches.

Connectors

ReelPak boom sections are joined together by a series of easy operating, stainless steel HingeLok Connectors. These strong, flexible connectors allow the boom to maintain its cylindrical shape from terminal end to terminal end in operation, transferring all of the fabric tensile strength along the full length of the connected boom sections and providing the best configuration for maintaining containment and a constant freeboard with the highest articulation in wind and waves.

ASTM design straight bar end connectors are installed at both the tow end Foam Filled Tow Adaptor (FTA) and the reel end Compacting Tow Adaptor (CTA).

Each tow bridle (TB) has a compatible ASTM end connector to assure interchangeability and adequate strength in towing. The bridles are secured to the ASTM connector ends of the FTA or CTA with stainless toggle pins.