Minibytes by Al Allen

And now…, for controlled burning! Yes, I am personally excited about this option because it has challenged and humbled me in so many ways over so many years. Even back in grade school, and later as a career move in the 1980’s, I could feel the incredible potential for “combustion”! We had not yet developed the tools and techniques (or the public & regulatory support) in the 80’s to explore the full potential for burning spilled oil. Worse, as a boy, I was more curious than wise. I have to laugh…, now…, as I think back to my youth (~ 8 to 12 years old) when the building of model airplanes was a popular hobby for kids. My folks and several neighbors soon discovered the imagination and enthusiasm I had for ways to eliminate old models and thus create more space in my room. Yes, I did accidentally ignite some dry fields, and I tested the fire-resistance of a neighbor’s roof while launching an ignited model plane from my backyard. Kids and matches – scary! I guess it is not surprising that I found a way later in life to get paid for burning things! Fortunately, my dad and a few nervous neighbors helped influence an early appreciation for “Controlled” burning!

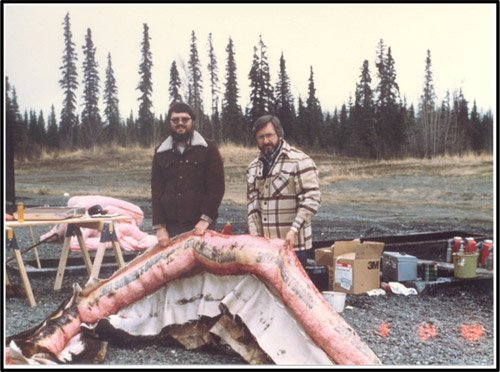

During the last 30 to 35 years the oil spill response community has witnessed the slow but steady development of good, safe and sound protocols as well as effective tools (i.e., fire boom and igniters) to carry out the controlled burning of oil spills. Such efforts have included many experimental burns as well as the controlled burning of spilled oil on land, in wetlands, and at sea. During these burns we realized that it was the thickness of the oil layer on water that determined the feasibility of sustained combustion and the efficiency of a burn. It was clear that we needed a fire-resistant boom that could survive temperatures approaching 2,000oF or more and still have the oil containment properties of a conventional boom in light to moderate seas. It is humbling to admit just how many boom designs and components we tested before we could contain even a small area of burning oil for just an hour or two. Photo 1 shows a typical 1st generation fire boom test in Kenai, Alaska (1983). Photo 2 shows the inspection of the boom’s remains by Wayne Simpson, a senior engineer with Shell Oil at the time, and me. These early efforts led to decades of small tank tests, larger and longer burns in pits, and eventually full-scale experimental burns at sea.

To the best of my knowledge, the first burn of a large accidental spill of crude oil at sea using fire boom was carried out during the Exxon Valdez Oil Spill in Prince William Sound (PWS), Alaska, in 1989. Approximately 30,000 gallons of crude oil were captured in a U-shaped configuration of fire boom well downstream of the spill source. The boom was towed slowly at about a knot between two fishing boats; and, when we were located a safe distance from any surrounding oil slicks, the contained oil was ignited with a small plastic bag filled with gelled gasoline (basically napalm). The bag was ignited carefully and released from one of the boom towing boats so it could drift back into the contained oil. Within minutes fire had spread over the oil, producing flames well over 100 feet high. The burn resulted in the elimination of approximately 95% or more of the contained oil in less than an hour.

That single burn was completed just before a storm moved in the following day, leaving widely spread patches of emulsified oil on the waters and shorelines of PWS. Most oils become difficult to impossible to ignite once they are weathered and emulsified to water contents in excess of 25% to 30% — needless to say, several attempts to ignite such weathered oil after the storm failed. The Exxon Valdez burn remained the only one of its kind on a major accidental spill using towed fire boom until 2010.

During the 21 years following the Valdez spill, the tools and techniques for controlled burning improved significantly during relatively small experimental and accidental spills. Then, when the BP blowout occurred during the summer of 2010, 42 miles offshore in the Gulf of Mexico, the response community was ready. We secured authorization to burn quickly and completed more than 400 controlled burns over a 3-month period. Photo 3 shows one of those burns. Through the summer as many as 20 burn teams would work throughout the day with 2 boom tending boats, about 500 feet of fire boom, and support personnel for ignition and documentation of each burn. Additional vessels and aircraft were used for Command and Safety, backup supplies, ignition and aerial surveillance/spotting functions. These efforts resulted in the elimination of more than 300,000 barrels of spilled crude oil.

As with the use of chemical dispersants, the controlled burning of spilled oil is a relatively simple option, capable under the right conditions of eliminating a lot of oil quickly and efficiently. However, it too has some significant shortcomings and constraints. To ignite and sustain combustion most oils must be thick enough (minimally 1/10th inch, and preferably many inches), relatively fresh and unemulsified, and contained by fire-resistant booms or natural barriers to prevent spreading during a burn. Fire booms, like conventional booms, must be towed at relatively slow speeds; and they are limited to the same wind-driven waves of about 3 to 5 feet where breaking waves can make containment most difficult.

As with the application of chemical dispersants, the burning of spilled oil must be approved prior to its use. Federal, state and even some local regulations will almost always have very strict and specific requirements involving minimum distances from populations, shipping lanes, certain facilities, etc. for controlled burning. Guidelines for air quality and the measurement/monitoring of smoke plumes will be enforced, and requirements will likely be in place regarding the recovery (or possible release) of floating burn residue upon completion of a burn. Water depth is not normally of concern as many burns have been approved in very shallow waters and in or near wetlands. Even large burns take several hours or more to raise the temperature of underlying water just a few degrees, especially where burns are conducted with booms under tow (i.e., with water continuously replaced beneath the fire).

As discussed in previous blogs, each of the three primary oil spill response options (skimming, dispersants and burning) are best implemented when supported by broad-range aerial surveillance systems and close-in “spotter” capability to maximize and maintain access to thick oil. In addition:

Physical removal is universally accepted and offers the potential for effective cleanup with a broad range of oil types and conditions in calm to moderate seas. Oil encounter rate with most skimming systems (due to relatively low operating speeds and swaths) may significantly reduce effectiveness with wide-spread oil slicks. Recovered oil must be stored, often transferred to backup storage vessels or barges, and disposed of. No authorization for use is required.

Chemical dispersants can be applied with high oil encounter rates and reasonably good efficiency on fairly fresh and naturally thickened oil slicks. They can be applied over extensive areas, even under relatively rough wind/sea conditions, but must be used in waters of adequate depth with good mixing energy. Careful consideration must be given to short-term elevated hydrocarbon concentrations in near-surface waters. Authorization for use is required, and special monitoring will almost always be required.

Controlled burning provides a high volume elimination technique where relatively fresh oil with little-to-light emulsification can be concentrated in calm to moderate seas. Oil encounter rate may significantly reduce effectiveness with wide-spread oil slicks (due to low areal coverage rates). Minor storage and disposal may be required for any recovered burn residue. Careful consideration must include possible short-term exposures of people and facilities to fire, and to the products of combustion. Authorization for use is required, and special monitoring of air quality will likely be required.

Alan A. Allen has over five decades of experience as a technical advisor and field supervisor involving hundreds of oil spills around the world. Al is recognized as a leading consultant and trainer involving oil spill surveillance and spotting techniques, the application of chemical dispersants, and the containment, recovery and/or combustion of spilled oil under arctic and sub-arctic conditions.

Copyright© 2018, Al Allen. Unauthorized use and/or duplication of this material without express and written permission from this blog’s author is prohibited.