How to configure an Elastec drum skimmer system

Elastec manufactures rotating smooth and grooved drum oil skimmer systems. They are configured for oil type, oil volume, location and other environmental conditions. Our systems are available with pneumatic, hydraulic or electric power sources. They are widely used for oil spill recovery, industial applications, and waste water treatment operations.

Drum skimmer system components

A drum skimmer system consists of three main items:

Smooth or grooved

drum skimmer

Pump

Power unit

When configuring a drum oil skimmer system, there are several factors to consider:

Oil skimmer in industrial tank

Location of oil

The location of the oil spill should be taken into consideration when choosing the size and model of drum oil skimmers. How difficult is the location of the spill to access? Is it inland, offshore or an industrial installation?

If the location is inland, it may require an oil skimmer that is portable or small enough to be transported with an ATV, like the Elastec TDS118 Drum Skimmer. If the spill is large and offshore, it may require a skimmer with a high volume recovery rate like the Elastec X150 Grooved Disc System.

For industrial situations, such as to recover trace oils, a smaller oil skimmer running continuously, like the Elastec MiniMax or Mini Skimmer, may be used. For larger industrial jobs, the Elastec TDS136 offers higher volume oil recovery. If the location has explosive vapors or flammable material, a pneumatic motor may be considered.

Contact us to discuss your project.

Type of oil and weather conditions

The type of oil to be skimmed will affect pump and drum type choices. There are four types of oil:

- Very light oils (jet fuels, gasoline)

- Light oils (diesel, light crudes)

- Medium oils (most crude oils)

- Heavy oils (heavy crude oil, Bunker C)

The type of oil and weather conditions will affect the oil’s viscosity. Cold weather will cause the oil to become more viscus and make it harder to pump. A heating source may be needed to help the oil flow. For light oils, the combination of a smooth drum and E150 submersible pump may work well. Heavy oil may need a configuration with a grooved drum and heavier pump, such as the Elastec ES400.

Contact us to discuss your project.

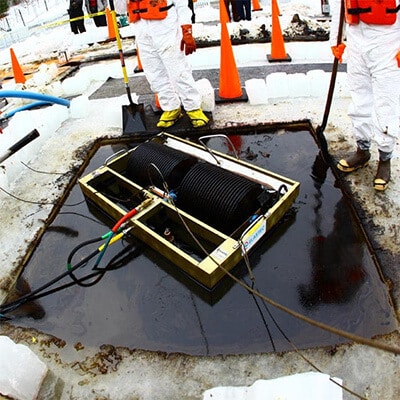

Oil skimmer in cold weather

Skimming a high volume of oil

Volume of oil and timeframe

The volume of oil to be recovered affects pump and skimmer selection. Drum skimmers with a large trough and pump are necessary to keep pace with recovery. If time is a critical factor, a skimmer system configuration that is able to recover large of amounts of oil in a small timeframe should be considered. The Bureau of Safety and Environmental Enforcement (BSEE) provides an Estimated Recovery System Potential (ESRP) mechanical recovery calculator.

If the skimmer is in an industrial pit, then consistency and resistance to any corrosive chemicals should be considered. The volume and speed of oil recovered will also affect storage options. Storage tanks will have to be emptied more often when quickly recovering large amounts of oil.

Contact us to discuss your project.

Power source

Another component to consider is the power source for the drum skimmer system. If a large vacuum truck is readily available, then a pneumatic skimmer system could be run from the vehicle’s air brake system. If the location is an industrial facility and electric power is readily available, an electric power pack could be used. For areas that do not have onsite electric or remote areas that are not accessible by vacuum truck, a diesel hydraulic power unit could be used.

Contact us to discuss your project.

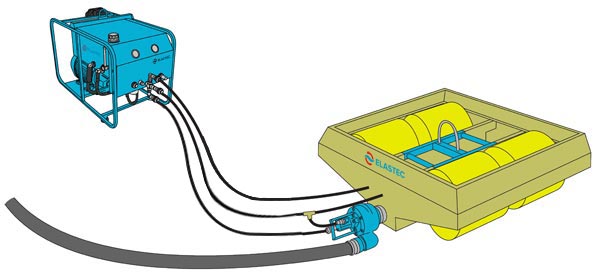

Diesel hydraulic power units

Elastec’s oil skimmer team will help configure a drum oil skimmer system, or an alternative system, that meets your specific spill requirements. Elastec offers several standard drum skimmer system configurations for most spill situations:

Diesel Hydraulic Configurations

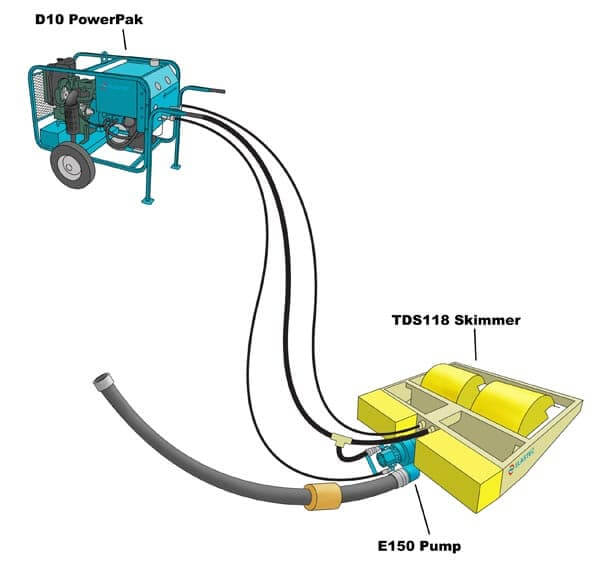

TDS118 (smooth or grooved drum) with D10 Diesel Hydraulic Power Pack and E150 submersible transfer pump.

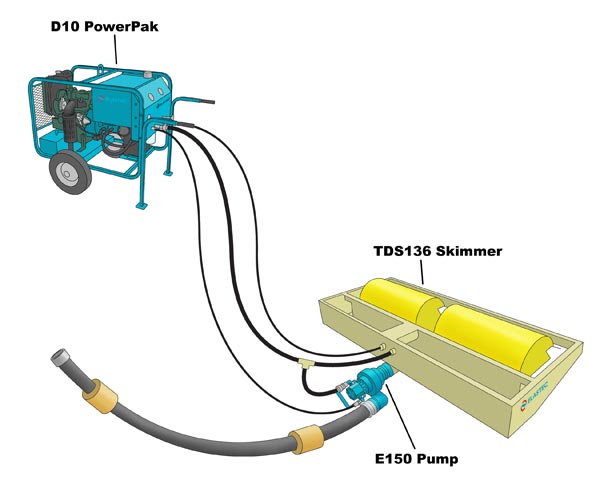

TDS136 (smooth or grooved drum) with D10 Diesel Hydraulic Power Pack and E150 submersible transfer pump.

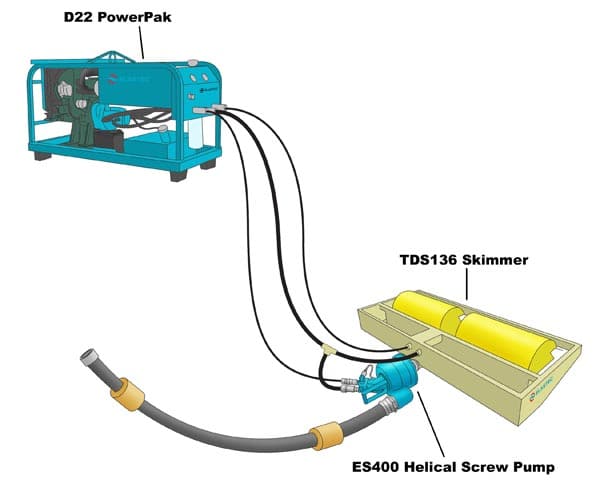

TDS136 (smooth or grooved drum) with D22 Diesel Hydraulic Power Pack and ES400 helical screw submersible transfer pump (heavy oil pump).

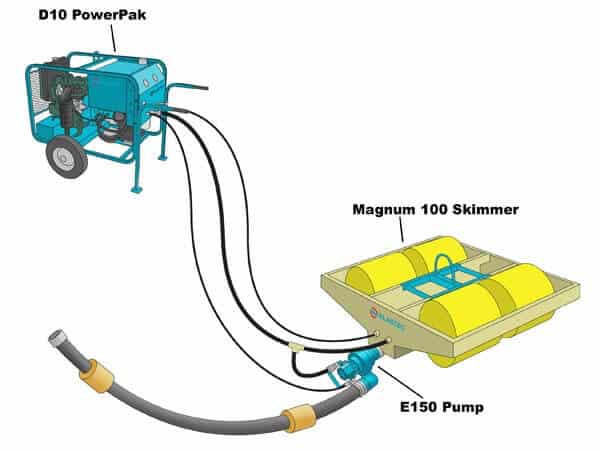

Magnum 100 (smooth or grooved drum) with D10 Diesel Hydraulic Power Pack and E150 submersible transfer pump.

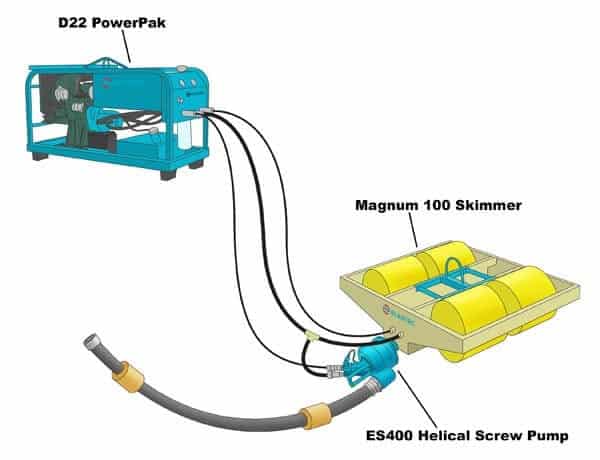

Magnum 100 (smooth or grooved drum) with D22 Power Pack and ES400 helical screw submersible transfer pump (heavy oil pump).

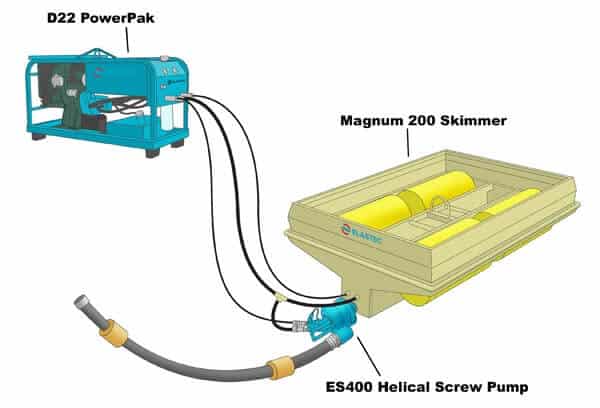

Magnum 200 (smooth or grooved drum) with D22 Power Pack and ES400 helical screw submersible transfer pump.

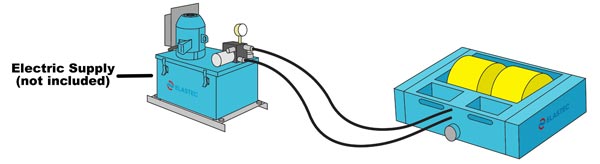

Electric Hydraulic Configurations

Skimmer with electric hydraulic power pack

The electric motor drives a hydraulic pump ( power pack ) which in turn provides hydraulic oil under pressure to drive the drums. The skimmed oil is drained from the back of the skimmer. The electric motor can be supplied with TEFC or Explosion Proof motor.

Electric hydraulic with submersible pump

Suction pumps have a limited suction lift, therefore in situations such as pits a submersible pump is coupled to the back of the skimmer that can pump the skimmed oil greater distances.

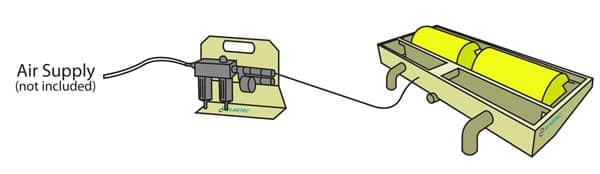

Pneumatic Configurations

Skimmer and Oiler Filter Kit

Compressed air is provided by the site. Oil collected by the drum is drained into a slotted pipe (API) or other.

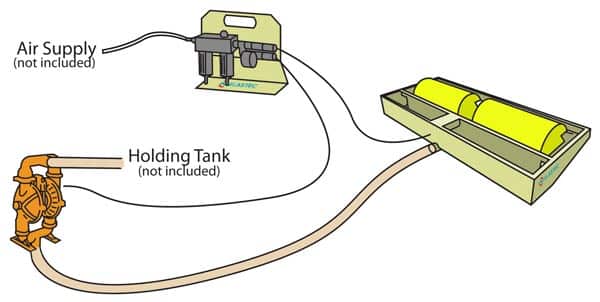

Skimmer, Oiler Filter Kit and pump

For situations where it is not possible to drain the recovered oil, an air operated diaphragm pump is included in the setup. Compressed air is provided by the site.

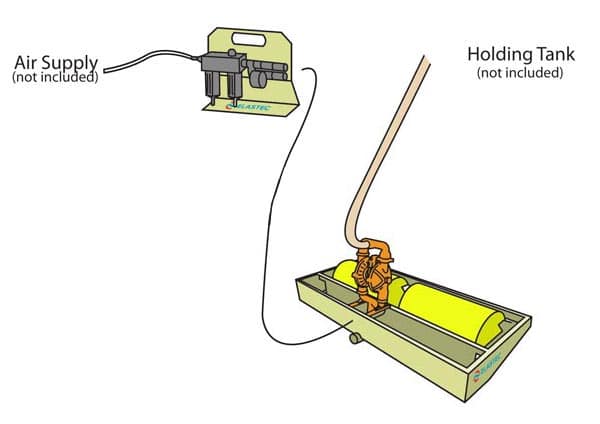

Skimmer, Oiler Filter Kit and mounted pump

Suction pumps are only able to draw up to 29 ft vertically, therefore in situations such as pits the pump is mounted on the skimmer and can pump vertically a greater distance. Compressed air is provided by the site.

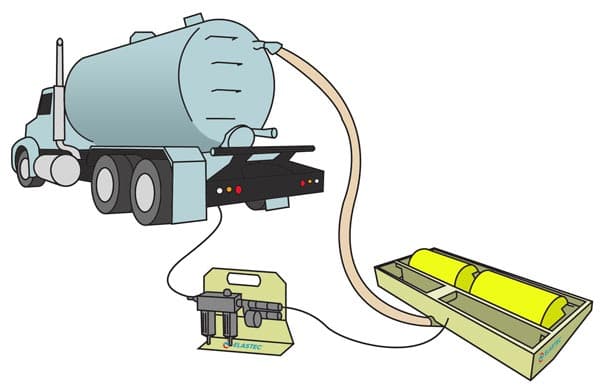

Skimmer and Oiler Filter Kit with vac truck

Compressed air is provided by the brakes from a vacuum truck. Oil collected by the drum sucked directly into the truck using its vacuum system.